When you have to get your products to their destination safely and efficiently, you need packaging that is up for the challenge. Two excellent options are corrugated packaging and flexible packaging.

What is the difference between the two, and what type of packaging is best for your products? Let’s take a closer look.

Corrugated packaging is a type of rigid packaging made from multiple layers of material — outer flat elements and a wavy inner layer that has been folded back and forth. A typical cardboard moving box, for example, is made from corrugated packaging.

Corrugated packaging is made from cellulose fibers — usually, the same pulp used to make paper. Sometimes this material comes directly from timber or wood shavings and sometimes from recycled corrugated packaging.

The two basic layers of corrugated packaging are the liner — the flat outer layer — and the medium or fluting — the inner, corrugated layer. An adhesive sticks these layers to one another. Some corrugated packaging is single-walled. Double and triple-walled packaging are also available to provide more sturdiness and stability.

The fluting comes in sizes A, B, C, E and F. The letters indicate the tightness of the folded material. With these corrugated packaging options, A-flutes have the loosest folds, while F-flutes have the tightest. Most single-walled corrugated packaging uses A, B or C-flutes.

Corrugated packaging is ideal for a range of commercial and industrial uses. Below are some of its main benefits:

Although corrugated packaging is an excellent solution in many scenarios, it has a few limitations:

Corrugated packaging is ideal for a wide range of commercial and industrial products. Below are just a few examples of items that ship well in corrugated packaging:

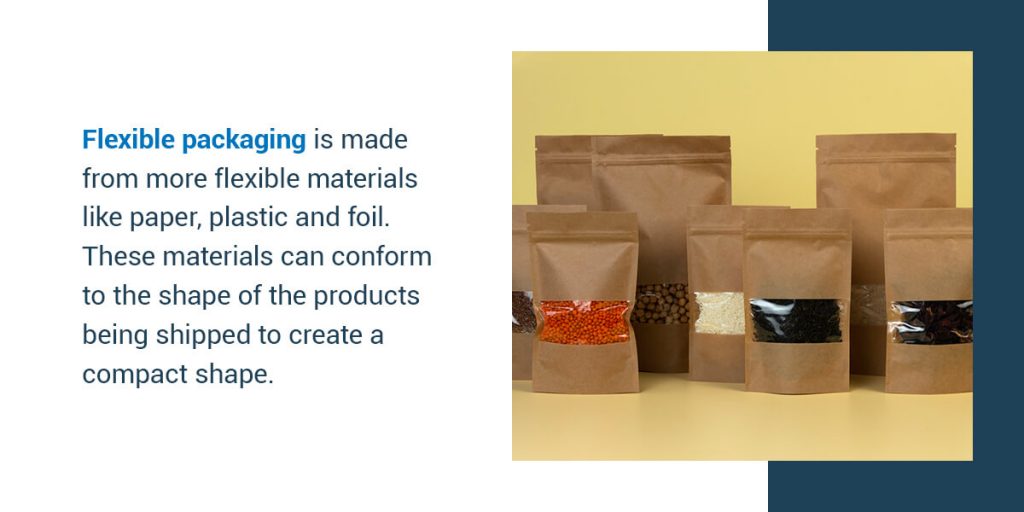

Flexible packaging is made from more flexible materials like paper, plastic and foil. These materials can conform to the shape of the products being shipped to create a compact shape. Bags, pouches, stretch film and liners are all examples of flexible packaging.

A few different flexible packaging materials are commonly used:

Below are some of the benefits of using flexible packaging for your company’s products:

Even though flexible packaging has numerous benefits, it also has a few limitations:

Below are a few examples of products that ship well in flexible packaging:

When your business needs reliable packaging for its products, make IPC your trusted source. We serve an extensive range of industries, offering everything from cannabis packaging to food and beverage packaging to industrial packaging.

We offer comprehensive stock services, including turnkey packaging and warehousing solutions. Alternatively, we will gladly work with you on custom packaging solutions to represent your unique brand, from customized boxes to labels to shipping. Our extensive industry knowledge and commitment to customer service mean you’ll get the professional treatment and expert advice you count on from your business partners.

Both corrugated and flexible packaging are excellent choices — the best packaging option depends on the products that go into them. We are happy to discuss your needs with you to help you find the right types of packaging for your business.

Request a quote today, or contact us to learn more about our packaging options.